LASER CUTTING & BENDING SERVICES

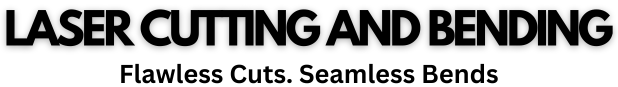

Precision laser cutting and CNC bending job work for sheet metal fabrication. High accuracy, fast turnaround, and custom solutions for all industrial needs

15 Years of Experience

We are Laser Job Cutting Services company located in Noida which provide excellent services in laser cutting throughout various industries. Shops with high speed laser cutting technology provide more precision, less time consuming and perfect finished product irrespective of the material & complexity required by the project.

Whether it is for the industrial application or for design purposes we have the capabilities to full fill them to the finest detail possible.

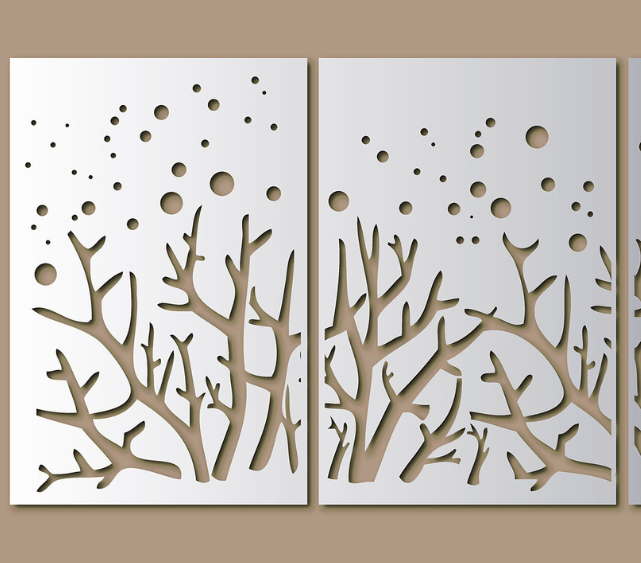

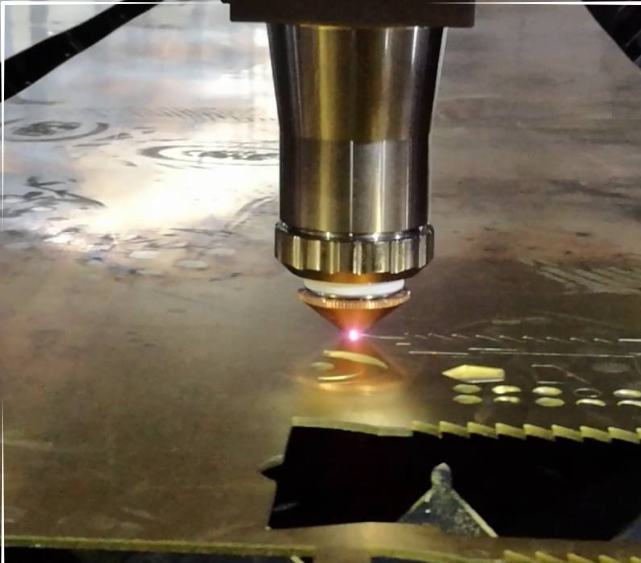

Metal Laser Cutting

Sharpness of various metallic surfaces, especially stainless steel, aluminum and mild steel for manufacturing, automobile, construction, etc.

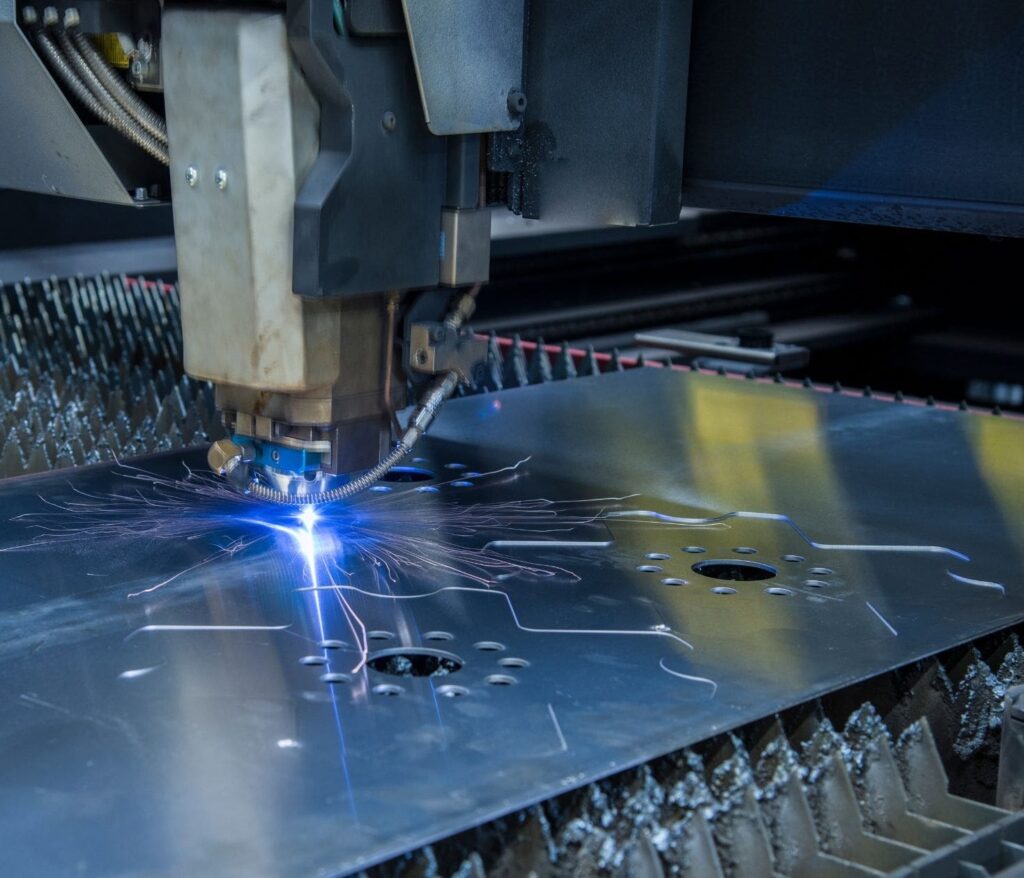

Custom Designs

Personalized? Innovative? Creative? Our advanced solutions will help you breathe life into your artistic, architectural and exclusive visions.

Non-Metal Laser Cutting

Specialized in cutting of acrylic,woods,plastics and the entire non- metal material for signage, décor and other projects

Bulk Production

Ideal for commercial projects that require homogeneity, quality assurance and short project delivery cycle.

Laser Cutting Machine Job Work: Precision Solutions Across Industrie

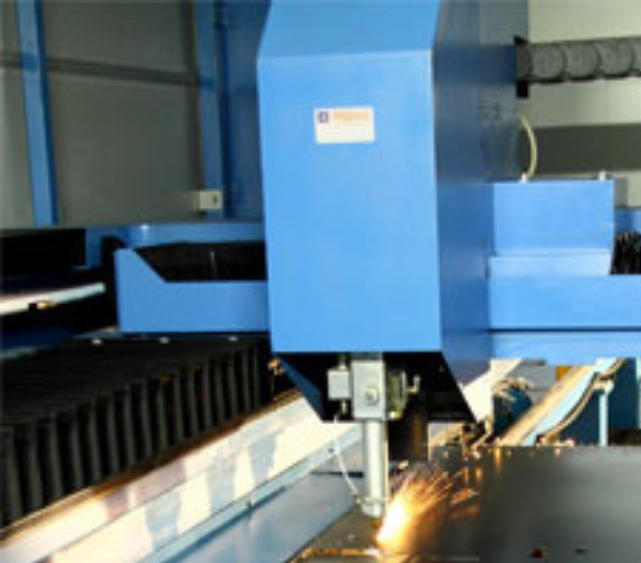

Laser cutting machine job work offers high-precision, efficient, and versatile fabrication solutions for a wide range of industries. Using advanced laser technology, complex designs and intricate patterns can be executed with exceptional accuracy on materials like stainless steel, aluminum, acrylic, wood, and more

Our Services

Custom Laser Cutting Machine Job Work at Competitive Rates

Metal Fabrication

Jig & Fixturer

SIGNAGE

ELECTRONICS

AUTO MOBILE

METAL FABRICATION

CONSTRUCTION AND INTERIOR

AGGRICULTURE INDUSTRY

Time has changed

FAQ

We work with a variety of metals including:

Mild Steel (MS)

Stainless Steel (SS)

Aluminum

Brass

Copper

GI (Galvanized Iron) For bending, we handle materials up to a specific thickness depending on the type and grade.

- Titenium Material

- Panel and Junction box

Mild Steel – up to 20 mm

Stainless Steel – up to 10 mm

Aluminum – up to 6 mm

(Capacity may vary based on the machine used.)

Our machines can handle sheet sizes up to 1500 mm x 3000 mm (or more, depending on your setup).

Yes. We accept DXF, DWG, or CorelDraw (CDR) files. Our design team can also assist in converting your sketches or samples into machine-readable files.

Yes, we offer independent bending job work as well. Just provide the material and the technical drawing.

Job work in

Laser Cutting and Bending

SS Laser Cutting Services

we are providing stainless steel laser cutting services in noida that are used in various industrial applications.

MS Laser Cutting Services

we are also providing MS laser cutting services in noida that are used in various industrial applications.

Steel Laser Cutting Services

We are offering steel laser cutting services in noida, up, india. We are expert in meatal cutting services

Aluminum Laser Cutting Services

We are offering Aluminum laser cutting services in noida, up, india. We are expert in meatal cutting services .

View Details

Steel Laser Cutting Services

We are offering brass laser cutting services in noida, up, india. We are expert in meatal cutting services .

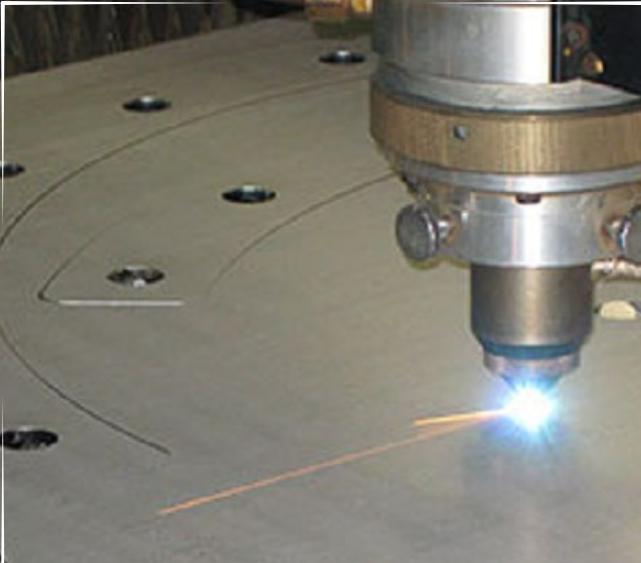

CNC Laser Cutting Services

We are offering CNC Laser Cutting Services in noida, up, india. We are expert in meatal cutting services .

Laser Cutting Machine Job Work – Industry Use Description

Laser cutting machine job work involves the precise cutting, shaping, and engraving of materials such as metal, plastic, wood, and composites using high-powered laser technology. This process is widely used across multiple industries due to its high accuracy, speed, consistency, and ability to handle complex designs.

Laser cutting services are essential in industries where precision engineering, mass production, and customized fabrication are critical. It allows manufacturers to produce components with intricate shapes and fine details without the need for additional finishing work, thereby saving time and cost.

Here’s how different industries benefit:

Automobile and Aerospace Industries rely on laser cutting for manufacturing lightweight and durable parts with tight tolerances, crucial for performance and safety.

Metal Fabricators and Construction Companies use laser cutting to create structural frameworks, customized designs, and heavy-duty components quickly and efficiently.

Electronics and Electrical Industries require highly precise, small, and delicate parts, such as circuit boards and enclosures, which laser cutting achieves effortlessly.

Medical Device Manufacturers benefit from laser-cut surgical instruments and implants, where precision can be a matter of life and death.

Furniture and Interior Designers use laser cutting for artistic, detailed work on metals, wood, and acrylic to create premium designs.

Signage and Advertising industries use it for producing attractive, durable signboards, logos, and displays with intricate cuts.

Jewelry and Fashion Industries take advantage of laser cutting to craft fine, detailed, and customized ornaments and accessories.

Energy, Shipbuilding, and Defense Sectors require robust, corrosion-resistant components which are accurately cut using lasers to withstand harsh environments.

Because of its versatility, repeatability, and efficiency, laser cutting job work is not only a preferred solution for mass production but also for small batch runs and prototypes.